Resources

| PDF - Printable Version of Case Study | Download |

| Product Types Used | Air Cannon Solutions , Air Cannons |

|---|---|

| Industry | Power Generation |

| Customer | Bay Shore Station, FirstEnergy Corporation Oregon, Ohio |

This 631 MW power plant uses petroleum coke – a refinery waste product – to fire its boilers. But the sticky material would build up on the walls of the chutes carrying it from the gravimetric feeders to the boiler. Instead of the 300 tph required, the feed rate would slow down to 75 to 100 tph, starving the boilers.

The plant staff resorted to frequent cleaning of the chutes. But even after a cleaning, material would begin to build up almost immediately and the chutes would begin to choke again. Within one eight-hour shift, the feed rate might be reduced to 75 to 100 tph again.

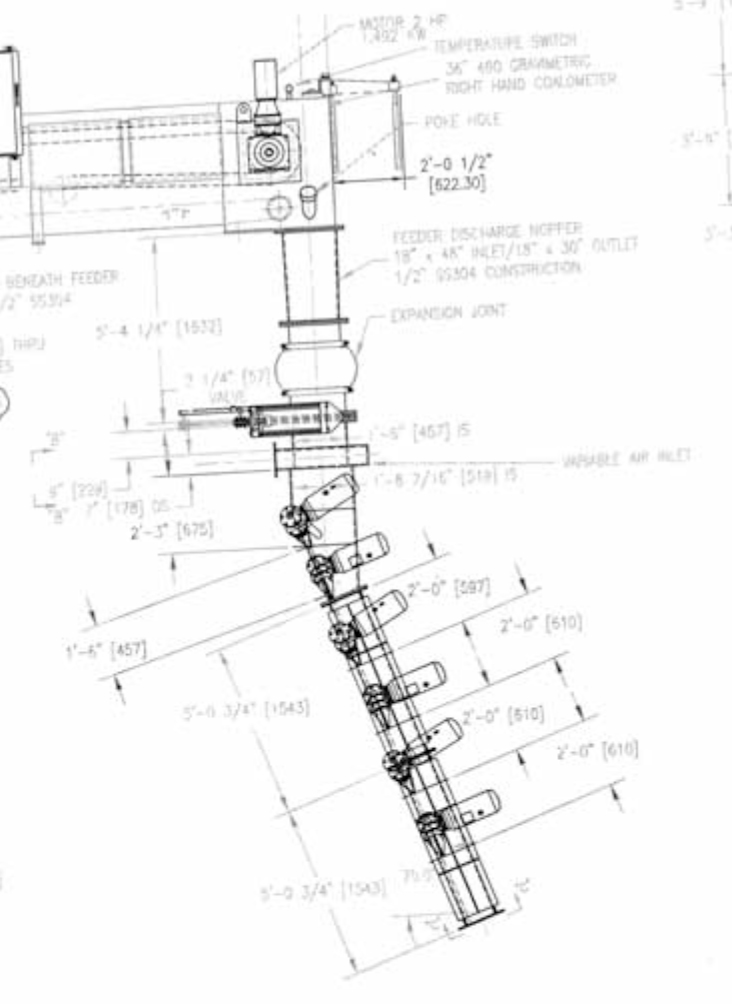

The Martin® Air Cannons are discharged in a cycle that calls for the two bottom cannons on a given chute to be fired together, with progressively higher air cannons fired individually at five-second intervals. After all cannons on a given chute are fired, the cycle moves to the next chute. After installation of the Martin® Air Cannons, the feeder system is operating as designed. The boiler unit has not tripped due to fuel shortage resulting from plugged feed chutes since the air cannon installation.

| PDF - Printable Version of Case Study | Download |

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.