Efficiency: The “fertilizer” that helps your profits take root and grow!

The worldwide demand for fertilizer rises and dips depending on a complex set of factors. Driven by agriculture, it’s an industry that shifts frequently with global economic trends, currency values, energy costs and even weather patterns. Overall, demand is projected to be strong in the near term due to a strengthening world economy and growing populations, as well as some crops, such as corn, being used as a source of energy.

The worldwide demand for fertilizer rises and dips depending on a complex set of factors. Driven by agriculture, it’s an industry that shifts frequently with global economic trends, currency values, energy costs and even weather patterns. Overall, demand is projected to be strong in the near term due to a strengthening world economy and growing populations, as well as some crops, such as corn, being used as a source of energy.

At the same time, however, global competition is also strong with the United States, Canada, China, India, Brazil, Trinidad and Tobago, Russia and Belarus among the largest exporters in the world. Because fertilizer production is a strong yet competitive business, finding an edge and maintaining profitability means you have to keep up with fast-paced demand while minimizing costs. That means getting more out of less, also known as “efficiency.”

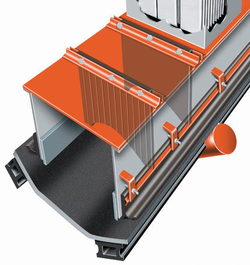

Fertilizer manufacturing is a complex operation, mainly because the three primary ingredients – nitrogen, phosphorous and potash – are processed so differently. Eventually, however, all three are processed into a granular form and moved by conveyor belts through a process that applies the coatings, mixes the product and packages it for shipping. When material spills from the conveyor belt, sticks to the belt past the head pulley or generates hazardous fugitive dust, operations have to be stopped for expensive unscheduled cleanup and maintenance.

Solving problems and improving efficiency is our mission!

Solving problems and improving efficiency is our mission!

At Martin Engineering, we design and manufacture durable conveyor belt equipment for manufacturing customers around the world. We have extensive experience working with complex conveyor systems including those used at fertilizer plants and providing solutions that make the process more efficient and more profitable. Our experienced engineers and technicians are dedicated to solving the kinds of problems that keep fertilizer plant managers awake at night, including belt carryback, spillage, fugitive dust, and accumulations that obstruct flow.

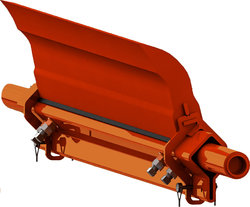

At Martin, we offer the most effective and durable products on the market for cleaning belts at the head pulley and minimizing dust problems. We also offer products that make transfer points more efficient and keep material flowing freely through your process with industrial vibrators and air cannons.

So if you’re having a tough time keeping material on the belt or preventing obstructions that slow things down, here’s the good news: It’s probably something we’ve already seen, and we’ve already figured out the solution. So pick up the phone and give us a call. We’d love to hear about your operation, the challenges you’re dealing with and what you’ve already tried to fix the situation. Then, we’ll get to work on providing you with an effective solution.

- Move material more efficiently along conveyor systems and minimize carryback

- Keep downtime for maintenance and belt cleaning to a minimum

- Reduce spillage and equipment damage by keeping conveyor belts aligned

- Manage airborne dust and minimize the risk of explosion and inhalation

- Eliminate the need for workers to enter confined spaces

- Prevent material from spilling off of moving conveyors

- Deliver more product by maximizing your plant’s overall throughput

- Reduce costs by minimizing waste and reducing energy consumption

- Eliminate excessive downtime for maintenance and housekeeping

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Our Replacement Blades Have the Lowest Cost of Ownership of ANY Blades on the Market

When you need replacement blades for your belt cleaners, why settle for anything less than the longest-lasting, most-effective cleaners in the industry, when they are competitively priced and all backed by multiple guarantees?

You’ll Find The Proof You Need To Compare Right Here

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!