Rise above the global competition and stay profitable with conveyors and transfer point solutions!

While international trade has been part of the global economy for centuries, imports and exports have expanded rapidly as technology has become more efficient and more sophisticated. In today’s economy, highly efficient industrial ports – located strategically on navigable waterways including oceans, rivers and lakes – are more important than ever. To maximize profitability, products must be moved quickly between ships or barges and railcars. This requires a highly complex, precise system of conveyor belts and transfer points capable of moving a wide range of products that includes everything from large containers to bulk materials over long distances, sometimes even more than a mile.

While international trade has been part of the global economy for centuries, imports and exports have expanded rapidly as technology has become more efficient and more sophisticated. In today’s economy, highly efficient industrial ports – located strategically on navigable waterways including oceans, rivers and lakes – are more important than ever. To maximize profitability, products must be moved quickly between ships or barges and railcars. This requires a highly complex, precise system of conveyor belts and transfer points capable of moving a wide range of products that includes everything from large containers to bulk materials over long distances, sometimes even more than a mile.

At a busy shipping port, whether it’s an independently run facility or owned by a mine or processing plant, equipment that is running inefficiently or breaking down causes numerous problems. If material that spills from the conveyor belt can’t be recovered and added back to the stream, that product is lost forever and lost product equals lost profit. Equipment that isn’t working correctly or is simply not designed well can also be a drag on efficiency, which means the ship stays in berth longer than necessary and slows down your load and unload times. Worker safety is also a concern when workers have to continually clean up fugitive material.

At Martin Engineering, our products are designed and manufactured to ensure conveyor belts operate cleanly and safely over long distances and optimize the efficiency of transfer and unloading points. By making sure your products move efficiently along the conveyor without spilling from the belt or accumulating into bottlenecks inside chutes and hoppers, we can help you prevent unexpected shutdowns for cleanup and maintenance. And since most industrial ports are on the water, containing bulk materials keeps it out of environmentally sensitive areas and keeps your operation within regulatory compliance.

We have extensive experience working with ports and terminals, so whatever challenge you may be facing, our professional engineers and technicians have most likely seen it, figured out the solution, and tested it to make sure that it works! And if you have a problem we’ve never seen, we love a new challenge! Contact a Martin representative to find out how we can apply our decades of experience to solving your problems today!

- Move material more efficiently along conveyor belt systems and minimize bottlenecks

- Keep downtime for maintenance and housekeeping to a minimum

- Reduce spillage and dust problems by keeping conveyor belts aligned

- Prevent material from falling off of moving conveyors

- Manage airborne dust and minimize the risk of explosion and inhalation

- Eliminate the need for workers to enter confined spaces

- Load and unload product faster by maximizing your plant’s overall throughput

- Reduce costs by minimizing waste and reducing energy consumption

- Eliminate excessive downtime for maintenance and cleanup

Martin® Belt Cleaner Requires Less Maintenance and Lasts Longer

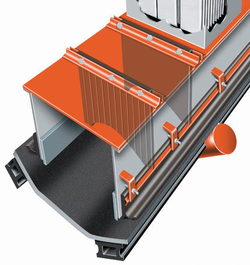

Belt Sealing Products Reduce Cleanup and Maintenance Costs

Transportation Company Needed Solution To Coal Dust

New Transfer Chute Improves Material Handling Operations

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Briefly Describe Your Application

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy