Resources

| PDF - Printable Version of Case Study | Download |

Problem Solved!

We've been solving bulk material handling problems for companies around the word for over 70 years. Learn more about some of their experiences below.

| Products Used | Tracker™ |

|---|---|

| Product Types Used | Transfer Point Solutions , Belt Alignment |

| Industry | Steel |

| Customer | Toranagallu, Karnataka, India |

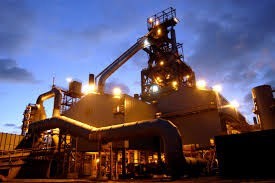

India’s leading integrated steel producer was having a belt tracking problem at its sintering plant located in the southern part of the country. With a capacity of 14.3 million tons per annum (MTPA) of bulk material, the main conveyor belt was becoming misaligned, causing excessive spillage and piles of fugitive material. To avoid equipment damage and potential safety issues, workers had to manually clean the area, resulting in regular and costly downtime and man-hours.

After surveying the problem, Martin technicians recommended the installation of two Martin® Trackers™, one upper and one lower, to keep the belt centered. The lower unit was installed on the conveyor’s return side, ahead of the tail pulley, and the upper unit was installed after the load zone. Martin® Trackers™ provided immediate and continuous correction of the belt’s path, thus preventing spillage, equipment damage and time consuming repairs and cleanup.

The Martin® Trackers™ have solved the problem of belt misalignment and spillage. Operators no longer have to shut down the plant regularly for cleanup. With less unscheduled downtime, production is optimized and labor costs are reduced. The client is very satisfied with the service and equipment provided by the Martin team. As a result, the company has ordered additional products and services.

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.+44(0)115 946 47 46

Martin Engineering Ltd.

Unit 33, The Tangent Business Hub

Weighbridge Road, Shirebrook, NG20 8RX

United Kingdom

Get Directions

info@martin-eng.co.uk

+44(0)115 946 47 46