| Products Used | Hurricane Air Cannon |

|---|---|

| Product Types Used | Air Cannon Solutions , Air Cannons |

| Industry | Cement |

| Customer | Çimentaş İzmir Cement Factory |

Problem

Çimentaş İzmir Cement Factory, established in 1953 as the first cement factory in the Aegean region with an initial production capacity of 150,000 tons, continues to operate today. The factory has a raw material crusher with a capacity of 600 tons per hour and an additive crusher unit with a capacity of 125 tons per hour. Crushed materials are stored in a closed stock area with a capacity of 400,000 tons. In the fuel preparation unit, petcoke and lignite coal are mixed and ground in specified proportions, and then fed into the rotary kilns along with alternative fuels (e.g. Waste Derived Fuel and waste oil). The factory operates two rotary kilns with daily production capacities of 2,300 tons and 3,200 tons, respectively, to produce clinker. The alternative fuels used in cement production were causing blockages in the preheater cyclones and calcining areas. These blockages had to be manually cleared using labor, which increased labor costs and created unnecessary health and safety risks. This situation negatively affected the factory’s overall efficiency

SOLUTION

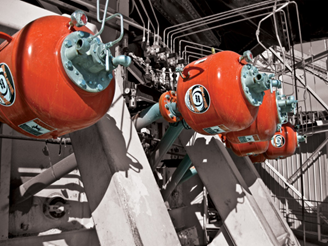

At Çimentaş İzmir Martin Engineering Turkey has been increasingly solving preheater blockage issues by installing a total of 124 Air Cannons throughout the plant. The introduction of Air Cannons completely eliminated the labor-related losses and health and safety risks caused by blockages. Regular maintenance is critical for ensuring the long-term efficiency of these Air Cannon Systems and as part of this, a periodic maintenance program called Martin Plus was initiated in March 2023 for systems that had not been serviced for an extended period. This program aimed to enhance system performance, and positive results were achieved. Ongoing maintenance services play a crucial role in maintaining the factory's operational efficiency.

RESULT

The Martin Plus maintenance service provided by Martin Engineering Turkey significantly improved the performance of the 124 Air Cannons. The system experienced a high failure rate before the maintenance services, but with the implementation of the periodic maintenance program, this rate was reduced to just 5%. Overall, with the Martin Plus maintenance service, an additional 1,925 tons of daily production capacity was achieved for both kiln lines. This improvement not only eliminated labor losses but also made a critical impact on operational efficiency and the continuity of Air Cannon System performance.