| Products Used | Hurricane Air Cannon |

|---|---|

| Product Types Used | Air Cannon Solutions , Air Cannons |

| Industry | Mining |

| Customer | RHI Magnesita Turkey Refractory Trade Inc. |

Problem

RHI Magnesita Turkey Refractory Trade Inc. operates in the İnönü District of Eskişehir Province. The company produces and sells raw magnesite, sintered magnesite, sprayable mortar, and slag plates. There are 3 shafts and 2 magnesite furnaces in the facility.However, due to adhesion and accumulation problems in the rotary kiln smoke chamber areas, the facility experiences production blockages. These accumulations reduce equipment efficiency and negatively impact production continuity. Additionally, manually cleaning the accumulated material causes time delays and poses risks to health and safety. This issue prevents the facility from fully utilizing its production capacity and lowers operational efficiency.

Solution

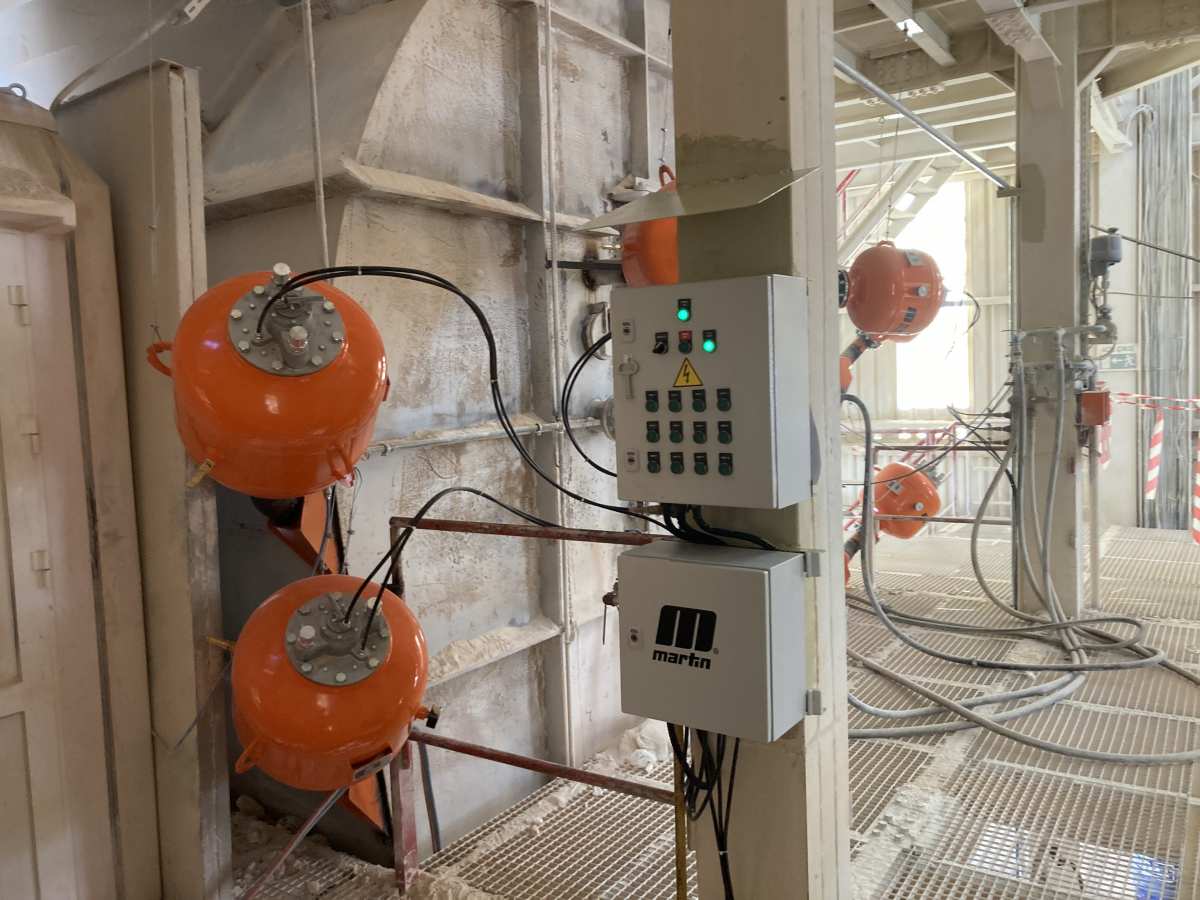

Experts from Martin Engineering Turkey thoroughly analyzed the areas in the rotary kiln smoke chamber regions where material adhesion is most intense. Based on these analyses, we recommended the installation of an array of Air Cannons to prevent material adhesion and ensure continuous material flow.Following technical assessments, a comprehensive system was designed and implemented using 12 Martin® Hurricane Air Cannons with 'positive pressure' firing technology. The system was designed to cover all wall surfaces where adhesion problems occurred. It works by applying sudden and high-pressure air blasts at regular intervals to keep the wall surfaces continuously clean and prevent material from sticking to the walls. As a result, the material adhesion issue in the smoke chamber area has been effectively resolved, leading to improved operational efficiency.

Experts from Martin Engineering Turkey thoroughly analyzed the areas in the rotary kiln smoke chamber regions where material adhesion is most intense. Based on these analyses, we recommended the installation of an array of Air Cannons to prevent material adhesion and ensure continuous material flow.Following technical assessments, a comprehensive system was designed and implemented using 12 Martin® Hurricane Air Cannons with 'positive pressure' firing technology. The system was designed to cover all wall surfaces where adhesion problems occurred. It works by applying sudden and high-pressure air blasts at regular intervals to keep the wall surfaces continuously clean and prevent material from sticking to the walls. As a result, the material adhesion issue in the smoke chamber area has been effectively resolved, leading to improved operational efficiency.

Result

After the implementation of the Air Cannon System, inspections revealed that the material adhesion and accumulation issues in the smoke chamber area were largely eliminated. Previously, due to the furnace cleaning hatch being opened for approximately 15-30 minutes every shift (8-hour interval), energy losses occurred. With the activation of the system, these energy losses were reduced to once every two days. This change has resulted in significant gains in both energy savings and operational continuity.Evaluation in terms of capacity and energy losses: Energy loss:Opening the klin doors for cleaning purposes for 15-30 minutes in each shift previously caused an increase in klin natural gas consumption during this time, and