Resources

| PDF - Printable Version of Case Study | Download |

| Products Used | Washbox™ Cleaning System |

|---|---|

| Product Types Used | Belt Cleaning Solutions , Specialty Belt Cleaners |

| Industry | Mining |

| Customer | Metal Mine in Western US |

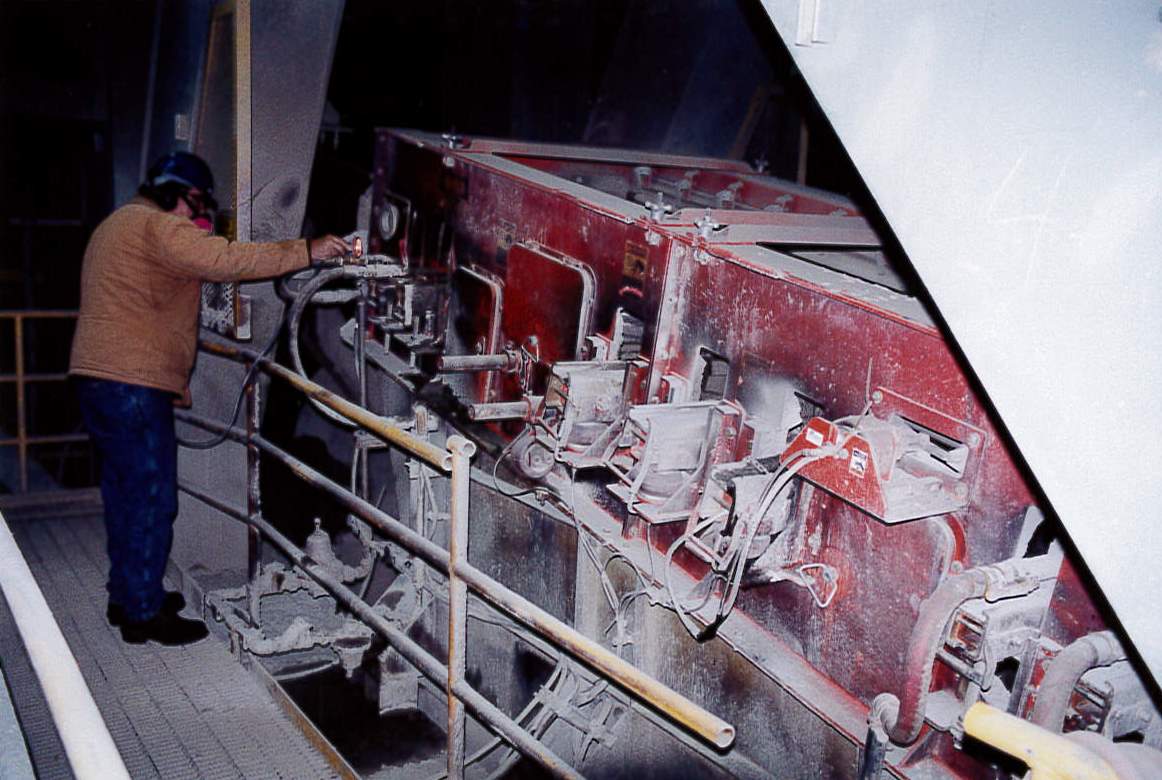

A metal mine in the Western US with long overland conveyors was having trouble with dust and carryback. The mine had to work with a high altitude location which resulted in cold weather and low humidity; long conveyor length; sticky material capable of hardening like concrete; and limited water. The claylike consistency of the crushed metal adheres to vertical surfaces and hardens like concrete. The way to remove it from the belt is to keep it wet. During the six month winter season at the mine’s high altitude, water must be removed from the belt to prevent freezing. At the same time, the low humidity could dry and harden the material on the belt. The belt cleaner would need to allow easy access without extended outages.

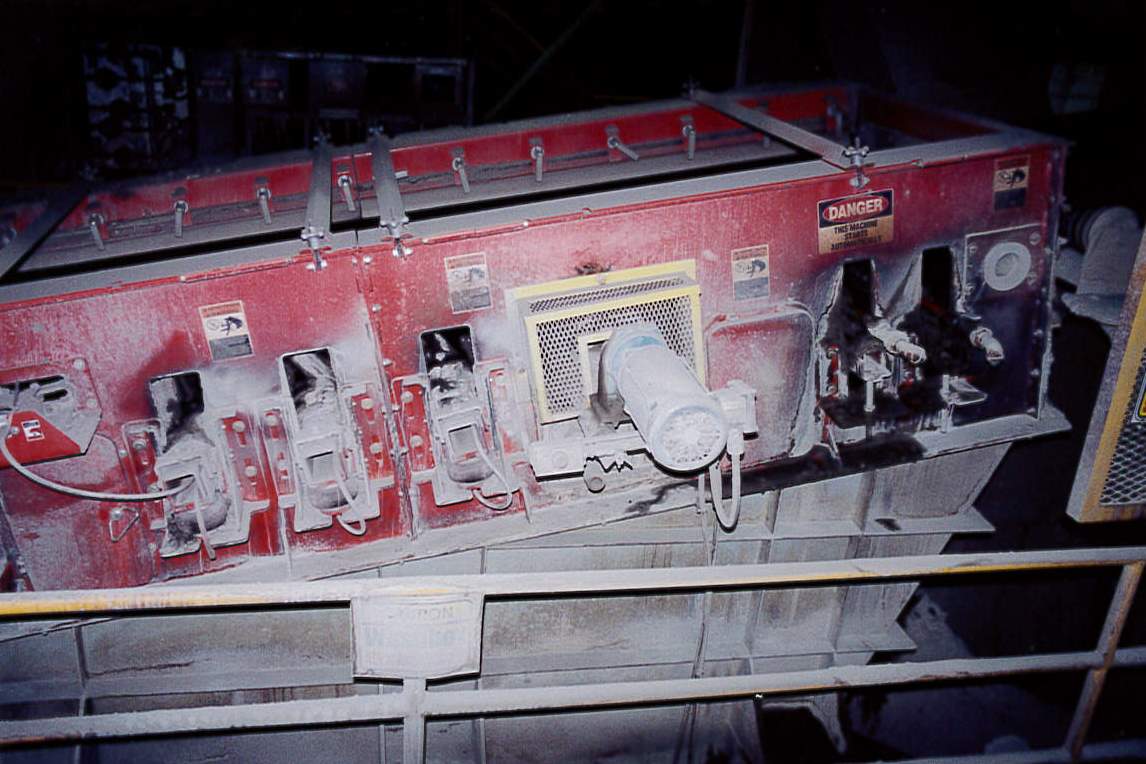

Shortly after starting its overland conveyor system, it became apparent that the project had to do more in controlling dust and carryback. It was determined that the overall operation would be better served with a system that washed the belt. This system would reduce the dust and eliminate the carryback left on the belt. Martin recommended the Martin® Washbox™ Cleaner. A series of belt-washing components are assembled in the washbox. They include two spray bars, a rotating brush, three belt cleaners and two air knives.

Given the conveyed material’s characteristics, the round-the-clock operating schedule and the challenging climate, the system designers knew the belt-washing station would not be perfect right out of the box. After several modifications, the system was stabilized. The system has demonstrated that it can be used in climates that drop below freezing temperatures. And it can be effective with very little water and energy. The efficiency of this belt-washing station provides the requisite control of fugitive materials to permit overland conveying.

| PDF - Printable Version of Case Study | Download |

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.